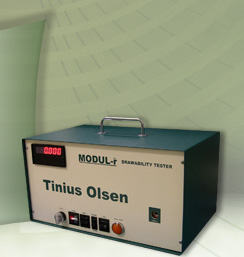

MODUL-r

The MODUL-r is the most efficient and economical “Go/No-Go” testing method available for determining if a given batch of sheet steel is suitable for a deep-drawing application.

The MODUL-r testing system helps cut potential material and production losses because it can accurately assess the drawability and earing characteristics of any carbon, or other magnetic, sheet steel in under 5 minutes! This compares extremely favorably with the three plus hours the same determination can take using conventional tensile testing methods.

Operation is extremely simple. First the operator prepares three test strips from a sample sheet. After marking the rolling direction across the sheet, three narrow test strips are blanked or sheared at 0°, 45° and 90° (for optimum ease, all three test strips can be punched at the same time using a punch press). The operator simply inserts the specimen into the test slot and presses the ‘Test’ button for a few seconds. The operator then records the resonant frequency which appears on the digital display and repeats for the remaining two specimens.

The MODUL-r uses a simple feedback system (called a magnetostrictive oscillator) consisting of a measuring head, an amplifier and an electronic counter. The measuring head consists of three coils that form the sample chamber. When the coil is inserted and the test button depressed, an alternating field is created by the current passing through the coil network, producing a cyclical longitudinal expansion and contraction in the sample through a process called magnetostriction.

These vibrations match the characteristic velocity of sound for that particular sample, or resonant frequency. This frequency is displayed on the front of the unit and is also used to control the oscillator circuit, stabilizing the output to a high degree of accuracy.