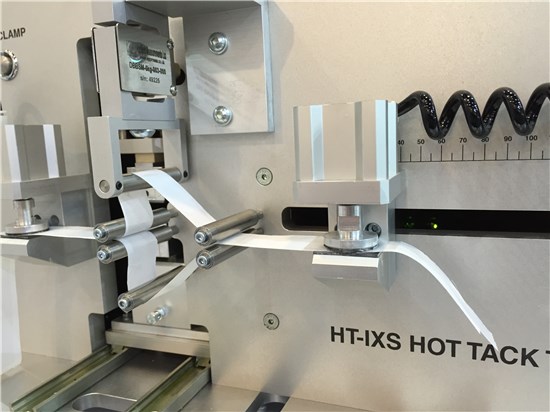

HT-1XS Hot Tack Tester

Touch Screen Precision Hot Tack Tester for determination of the hot tack seal strength of flexible packaging materials, to ASTM F1921.

In vertical (VFFS) and horizontal (HFFS) form-fill operations, heat seals are often subjected to forces whilst still hot. If the hot seals are unable to resist these forces then unsealed areas or holes into the package can occur during the process. The RDM HT-1XS Hot Tack Tester measures the strength of hot seals enabling selection and compliance testing of suitable flexible materials for packaging applications. Precise control of sealing process variables (temperature, pressure, and time) in production then enables an optimal balance between material specification, packaging machine speed and seal integrity.

Accuracy and repeatability in laboratory heat seal testing is vital, and the HT-1XS provides the technology and reliability to deliver time after time. The HT-1XS seals and then immediately measures the peel strength of the hot seal. An intelligent controller and touch screen user interface provide test setting options, and allows multiple settings to be stored for later recall. Resulting graphs and data of load v time and load v temperature can be viewed, printed and exported to spreadsheets / SPC systems.

Testing is performed in accordance with ASTM F1921. The RDM HT-1XS Hot Tack Tester is used by leading film producers and converters across the world, and is backed by our direct support offices and by our trained service partners worldwide.

Specifications:

Touch Screen Panel: LCD, 256 colour QVGA, 320 x 240 pixels, 14.48 cm diagonal viewing. Touch screen, analogue resistive (gonze) with serial controller. Processor geode SC2200. 266 MHz MMX compatible. 64 Mb Dram main memory.

Heat Sealing Process: Temperature range – ambient to 250 deg. C +/- 1 deg C reading to 1 deg C, RTD input (deg F can be selected via the screen). Pressure range – 0 to 100 psi +/- 5 psi (other units can be selected via screen). Dwell Time range – 0 to 99.999 sec +/- 0.1 sec. Heat sealing head pneumatically operated to extend for heat sealing cycle and then return to rest position. Ensures heat is not influencing seal whilst waiting for pull cycle or when cold peel test option selected.

Sealing Jaws: Heated upper and lower ground flat aluminium jaws 25 x 50mm, supplied as standard. Jaws have an interchangeable feature which enables crimp jaws or custom-ised jaws to be fitted. Alignment of jaws made through spring mounted lower bolster. Teflon coating of jaws is an option.

Hot Tack Measuring: Load cell ‘Z’ bend strain gauge range - 2000g or 5000g (20N or 50N) +/- 0.25%. Pull speed range – 1mm/sec to 1000mm/sec. Manual or automatic return of cross arm to start position. Maximum cross arm travel – 100mm. Travel indication shown on main display panel in mm. Delay on pull range – 0 to 99min 99sec.

Film clamps: Left and right pneumatic clamps synchronised with pulling operation.

Cold Peel: Allows seal to completely cool and cure before pulling operation takes place producing cold seal strength measurement. Cooling Range – 0 to 99hrs 99mins 99sec.

Safety Guard: Micro-switch controlled guard in position feature.

Environment: 5-50C ambient operating temperature, RH 75% max (non-condensing)

Power: 110V AC or 230V AC 50/60 Hz 1000W

Accessories supplied: 1000g calibration weight. 25mm x 350mm sample seal template

Options available: Crimp jaws 25 x 50mm, 120 deg x 1.8mm pitch. Teflon coating to sealing jaws. Silicone rubber covered lower jaw.

HT-2PC Automatic Hot Tack Tester

Hot Tack Tester with automatic film feeding device for determination of the hot tack seal strength of packaging films, to ASTM F1921.

The HT-2PC Hot Tack Tester is a highly technical instrument designed to measure the ‘Hot Tack Seal Strength’ of flexible packaging materials. It follows the principles of ASTM F1921 Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and blends comprising the sealing surfaces of flexible webs.

What is Hot Tack Seal Strength?

Hot Tack Seal Strength is a measure of the strength of a hot heat seal tested within milliseconds after heat sealing. On production packs, newly formed hot seals are frequently exposed to disruptive forces, such as when contents are dropped into the pouch. These force act on the hot seal and if there is inadequate resistance they can break all or part of the seal. Therefore it is essential to measure the amount of stress the seal can withstand.

The HT-2PC has been designed to test the hot seal strength under accurately controlled conditions, simulating the stresses a pack is exposed to on a high speed packaging line. A heat seal that has cooled to ambient temperature will reach its maximum seal strength after several minutes or even hours. Measuring strength of cooled seals prepared on a Lab Heat Sealer and tested on a separate Tensile Tester does not correlate with the strength of a hot seal.

Principle of Operation

HT-2PC Automatic Hot Tack Tester replicates the heat sealing processes employed on automatic packaging lines in particular VFFS packaging machines, combined with a high speed tensile tester.

The operator chooses (or creates) a ‘parameter template’ from the library which sets the machine to test at defined values for temperature, pressure, dwell time, cooling time and peeling speed. The template can be a Single Test, Replicate Test, Sequential Test or Seal Initiation Test. These are then loaded to the ‘Playlist’. Film is loaded either manually for a single test, or a long strip is wound onto the film feeding device.

Once the playlist is started everything is sequenced automatically. The film is pushed into the sealing jaws, and is clamped. The hot sealing bars close to the desired pressure and after the dwell time elapses the jaws open. Next, the programmed cooling time runs down and then the sealed film is peel open at the test speed. All measurements of the seal properties are recorded at high speed to ensure transient forces are captured accurately. The results are displayed and saved automatically on the industrial pc, and saved for later recall, reporting or export to other software. The playlist then increments to the next test, the film is indexed to the next position and the test sequence starts again.

Parameter Templates

Parameter templates are used to load the required test settings. These are Single Test, Replicate Tests, Sequential Tests or Seal Initiation Tests. PLC control of all the parameters enables simulation of production packaging machines. A wide range of setting for each parameter enables testing of various materials to suit each application:

• Sealing temperature for top and lower sealing jaws, set individually.

• Sealing pressure

• Sequence timers for Delay Time, Dwell time, and Cooling Time

• Peeling speed

• Output configuration

Automatic Film Feeding Device

The Film Feeding Device is conveniently located in the front panel allowing easy use and access to the most frequently used parts. The clamps are easily loaded and clamp the film automatically once the test has been activated. Vertical movement of the lower clamp is controlled by an electric motor that enables accurate positioning and speed control through an encoder. The film folding devices sets the film up ready for sealing and the sealing is made through The sealing bars incorporate the heating element and sensors to complete the feed back loop of the PID temperature control.

Data Capture

The software is designed to be user friendly with drop down menus and easy key-strokes. The software is con-trolled through the touch screen (or keyboard and mouse) for parameter setting, measuring and data recording and storing for later recall. The software enables efficient use of the instrument by any person involved in testing, from production machine operators to quality control and R&D personnel. Report-ing is via a clear easy to read graphical media which shows each test and at the end of the test or series an overlay of test results.

Benefits:

Automatic film feeding for fast, operator independent test results.

Up to 40 hot tack tests per strip without need for operator supervision, with film sensor that pauses if the film breaks or runs out.

‘Parameter templates’ for Single Test, Replicate Test, Sequential Test and Seal Initiation Test, giving simple and fast set-up.

A playlist (like a music playlist), that automatically advances tests.

Fully automatic PLC control of all test parameters

Industrial PC with USB and Ethernet connectivity

Meets standard ASTM F1921

Features:

Easily exchangeable jaws

Low maintenance

Easily calibrated

Optional film feeder for fully automatic measurements

Industrial PC with 15" touch screen

10mm wide seal x 40mm long as standard (5mm and 15mm optional)