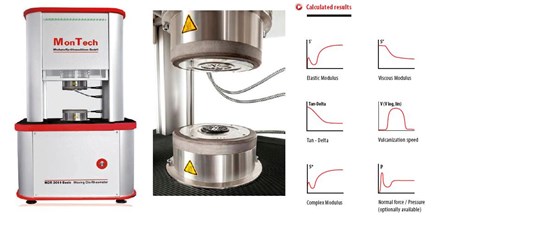

MDR 3000 Basic Moving Die Rheometer MDR 3000 Moving Die Rheometer

MDR 3000 Basic Moving Die Rheometer

ISO 6502 | ASTM D 5289 | DIN 53529

The MDR 3000 Basic Moving Die Rheometer (MDR) produces all necessary rubber vulcanization data for any rubber or elastomeric compound. The MDR curve analysis is essential for molders, extruders and others to ensure their compounds will cure or process as intended. Outfitted with user friendly software and advanced rheological technology, the MDR 3000 Basic is perfect for quick quality checks and simple research applications.

Brushless DC Motor with integrated drive control system ideal for static testing

Fanless aerospace grade aluminum and stainless-steel framing for tough production environments or laboratory settings

Easy to use instrument control software with integrated self-diagnostics

Equipped with state-of-the-art programmable logic controller for the fastest data sampling rate

Furnished with intelligent transducer technology for the highest measurement precision

Includes MonControl LIMS instrument management software

Completely modular for automation technology

Host-system linkable for easy integration into any laboratory

Technical Specifications

|

Standards

|

ISO 6502 | ASTM D 5289 | DIN 53529

|

|

Test Chamber

|

Bi-conical, closed System

|

|

Electrical

|

Single phase 220 V - 230 V, 5 Amps

|

|

Pneumatics

|

min. 4.5 Bar / 60 psi

|

|

Electrical

|

Single phase 220 V - 230 V, 5 Amps

|

|

Drive System

|

Mechanical, brushless DC eccentric drive

|

|

Sample Volume

|

approx. 4.5 cm3

|

|

Torque Range

|

0.01 to 235 dNm | 0.01 to 208 in.lb

|

|

Oscillation Frequency

|

1.667 Hz (100 cpm)

|

|

Oscillation Strain

|

+/- 0.1°, 0.2°, 0.5° (Standard), 1° or 3°, Mechanically adjustable (+/- 1.4%, 2.8%, 7% (Standard), 14% or 42%)

|

|

Measured Data

|

Torque (dNm, lbf.in, kgf.cm), Temperature (°C, °F), Pressure (bar, kg per cm²), Time (min - min / min - sec / sec), Shear rate (1/s, rad/s), Cure rate (1/min, 1/sec)

|

|

Calculated Data

|

S΄, S˝, S*, tan δ, phase angle, cure speed, ...

|

|

Data Points

|

Over 3500 data points available for each test Including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90

|

|

Data Interface

|

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (optional)

|

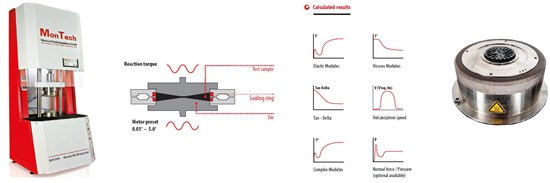

MDR 3000 Moving Die Rheometer

ISO 6502 | ASTM D 5289 | DIN 53529

The MDR 3000 rubber moving die rheometer features the tough 3000 series frame made of stainless steel and aerospace grade aluminum. The software programmable MDR motor drive system allows the oscillation strain to be preset from 0.01 to 5.0° while achieving unmatched accuracy and repeatability. Rubber curing systems like the MDR 3000 show the optimal cure time of rubber and its related data points necessary for demanding quality control and research applications.

Advanced Features & Applications

Rugged 3000 series machine frame for the most stable readings in laboratories or the harshest production environments

Fanless and sealed housing, preventing debris from entering critical systems

Patented MonTech wearless direct torque drive motor

Software programmable strain modification (0.01° to 5.0°)

Internal diagnostic and condition monitoring routines

Optional cooling systems

Includes MonControl LIMS instrument management software

Designed for compatibility to any host-system for quick implementation into the laboratory or production floor

Technical Specifications

|

Standards

|

ISO 6502 | ASTM D 5289 | DIN 53529

|

|

Test Chamber

|

Bi-conical, closed System

|

|

Electrical

|

Single phase 220 V - 230 V, 5 Amps

|

|

Pneumatics

|

min. 4.5 Bar / 60 psi

|

|

Electrical

|

Single phase 220 V - 230 V, 5 Amps

|

|

Drive System

|

Mechanical, brushless DC eccentric drive

|

|

Sample Volume

|

approx. 4.5 cm3

|

|

Torque Range

|

0.01 to 235 dNm | 0.01 to 208 in.lb

|

|

Oscillation Frequency

|

1.667 Hz (100 cpm)

|

|

Oscillation Strain

|

+/- 0.1°, 0.2°, 0.5° (Standard), 1° or 3°, Mechanically adjustable (+/- 1.4%, 2.8%, 7% (Standard), 14% or 42%)

|

|

Measured Data

|

Torque (dNm, lbf.in, kgf.cm), Temperature (°C, °F), Pressure (bar, kg per cm²), Time (min - min / min - sec / sec), Shear rate (1/s, rad/s), Cure rate (1/min, 1/sec)

|

|

Calculated Data

|

S΄, S˝, S*, tan δ, phase angle, cure speed, ...

|

|

Data Points

|

Over 3500 data points available for each test Including S‘ Min, S‘ Max, TS 1, TS 2, TC 10, TC 30, TC 50, TC 90

|

|

Data Interface

|

Ethernet (10/100 MBit), USB (int.), CF card (int.), RS232 (optional)

|