Benchtop Single Column up to 10kN Benchtop Double Column 5kN to 125kN

Bench Top Testing Machines 5 to 10kN

The LFM-L Single-Column Systems are designed for testing of a variety of different materials, specimens or components where load requirements are low.

This series is compatible with a wide range of accessories, grips and fixtures covering all relevant applications as testing of rubber, plastics, foils, films, textiles, adhesives, paper, foods, foams, timber, wires or other metallic or non-metallic specimens as well medical, electronic and other components.

Key Features

Rigid machine frame with high stiffness providing superior axial and lateral stiffness and guarantees robust, durable and long-term operation

Precise linear modules with backlash-free ball screw assembly provides high load capacity, high positioning accuracy and repeatability

Controlled by a high responsive servomotor to drive the mobile traverse (crosshead) providing faster starts and stops, best control, and highest accuracy at a extremely low noise level

Additional guiding columns for increased lateral stiffness

Compact and rigid extruded aluminium profile (frame) with T-slots to easy mount furnace or extensometer mounting brackets, digital hand wheel, cable duct, or any other accessories and attachments

Spindle / linear module protected by corrosion-resistant steel strip over fully crosshead stroke

Precision strain gauge load cell mounted on movable crosshead but also fits to lower base platen

Digital displacement (movable crosshead) measuring system

Upper crosshead can be mounted at several positions to optimize the vertical test space depending of used grip or fixture

Standardized mounting stud (male) Ø20/8 mm to mount accesories

Ability to drive crosshead at various speeds

Adjustable and end-stops in both (UP/DOWN) directions for the best protection of operator, test sample and machine

Overload Protection

Easy one-point in-service lubrication of the precision ball screw assembly

Durable structured coating (or paint)

Use of high quality components and assemblies of reputable companies

Bolts for lifting the machine

Adjustable machine feet to level the testing machine

The machine is free-standing and can be placed onto stable table

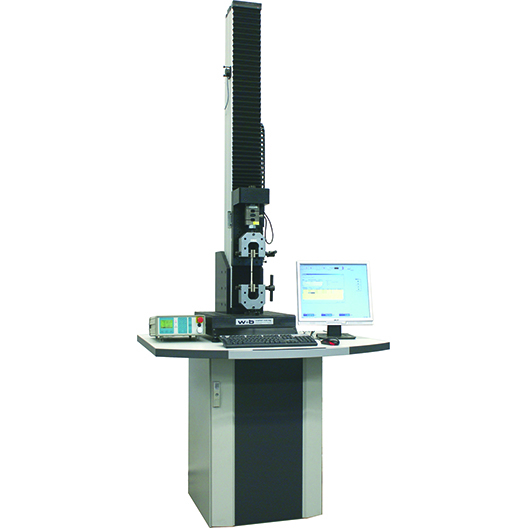

LFM-Top Electromechanical Table-Top Machines 5kN to 125kN

Designed for materials and components testing the LFM-TOP Dual Column Table-Top Systems can be used over a range of force applications up to 125 kN.

The LFM-TOP test systems are supplied with two backlash-free ball screws and additional two guidance columns providing suitable load frame stiffness as required for table top design.

The mobile crosshead is driven by a state-of-the-art brushless / maintenance free AC Servomotor providing high positioning accuracy and

repeatability, faster starts and stops, best control, and highest accuracy at extremely low noise level.

The LFM-TOP series is modular constructed and can be configured with a variety of grips and fixtures, extensometers, environmental chambers, high temperature furnaces, different software packages and other accessories to suite your specific testing needs.

Key Features

Rigid machine frame with high stiffness providing superior axial and lateral stiffness and guarantees robust, durable and long-term operation

Two backlash-free ball screw assemblies provides high load capacity, high positioning accuracy and repeatability

Controlled by a high responsive maintenance-free AC servomotor to drive the mobile traverse (crosshead) providing faster starts and stops, best control, and highest accuracy at extremely low noise level

Two additional steel guiding columns for increased lateral stiffness

Spindle / Column protection over total traverse stroke

Precision strain gauge load cell mounted on movable crosshead

Digital displacement (movable crosshead) measuring system

Standardized mounting studs (male) for easy and flexible mounting of grips and fixtures

Adjustable end-stops in both (UP/DOWN) directions for the optimal protection of operator, test sample and machine

Emergency stop direct at the machine

Overload Protection

Easy one-point in-service lubrication of precision ball screw assembly

Durable structured coating (or paint)

Use of high quality components and assemblies of reputable companies

Bolts for machine lifting

Adjustable feet for leveling Testing Machine

The machine is free-standing and can be placed onto stable table

Optional additional 2nd test space for increased flexibility and efficiency