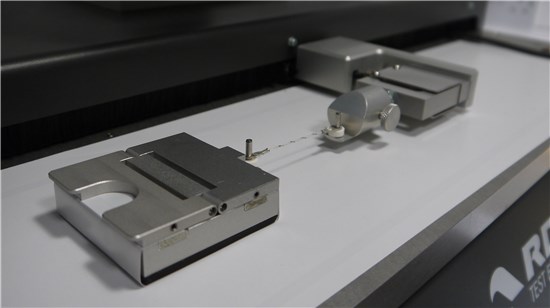

CF-800XS Precision Friction Tester

Touch Screen Precision Friction Tester for determining Static and Kinetic Friction of packaging materials to ASTM, BS, ISO and TAPPI standards

Testing to ASTM D1894, ISO 8295, TAPPI T549 and BS2782-824A, and more.

The successful processing of flexible films or paper and board is largely dependent on the correct coating of ‘SLIP’ additives applied to the material. The successful forming of the material requires easy sliding or flow over formers on the packaging machine where at high speed acute angles can change the direction of flow to produce a tube or pouch. The application of ink on the film, will cause the properties of slip to change, therefore the need to measure and control Coefficient of Friction is paramount.

Accuracy and versatility in testing is vital, and the CF-800XS provides the technology and range of options to deliver for your specific needs. An intelligent controller and touch screen user interface stores multiple settings for later recall, and controls settings to ensure calibrated accuracy to international testing standards.

Benefits:

Versatility to meet ASTM, BS, ISO and TAPPI standards

Integral controller and data analysis for stand alone use in laboratory and production environments, optional pc data acquisition

Convenient built in graphical display of test data and trends over multiple samples

Simple test set up and memory of settings for later recall makes switching between methods fast

Low Maintenance - 12 months between calibrations

Features:

5.7" touch screen controller for precise control and measurement of force, distance and speed

Memory recipe function for quick and accurate recall of settings

Vacuum suction across the test bed for fast clamping of test material

Optional heated test bed for determination of 'Hot Slip' values.

Specifications:

Bed Material: Natural anodised cast aluminium

Sled Material: Anodised aluminium with foam contact pad with density of 0.25/cm

Speed Control: 10 – 1000mm/min +/- 10mm/min

Force Reading: 0-1000.0 grammes +/- 0.25% Fro (other loads can be specified)

Coefficient of Friction Reading: Calculated value from sled used 0-1.00 +/- 0.25% Fto

Touch Panel: LCD, 256 Colour, QVGA, 320 x 240 pixels, 14.48cm diagonal viewing.

Screen: Touch screen, analogue resistive (gonze) with serial controller. Processor Geode SC2200. 266 MHz MMX compatible. 2 mbyte, on board flash memory for firmware. 64 MB Dram main memory.

Vacuum: Air pressure of 80 – 100 PSI supply with venture generated vacuum pulling +90 % vacuum

Temperature: Ambient to 100ºC +/- 5ºC (when specified)

Drive: DC synchronous motor/gear box driving ball screw and crosshead. Speed Feedback: Via in line encoder

Output: RS232 C

Power: 240 VAC single phase 50/60 Hz (110V AC available on request) 0.75 KW max

Environment: 5-50°C ambient operating temperature, RH 75% max (noncondensing)

CF-200i Inclined Plane Coefficient of Friction Tester

The CF-200i Inclined Plane Co-efficient of Friction Tester determines the static friction properties of plastic films, foils, laminates, papers and boards.

The equipment performs tests to recognised International Test Standards including ASTM D4918, G219, TAPPI T815, T503, T548 and NFQ 03083.

Introduction

Slide angle friction is a measurement of a sheet like substrate such as paper, plastic film, thin board, corrugated board etc. which determines the angle of inclination at which one substrate affixed to a sled will begin to slide/slip against another substrate of a similar material affixed to a bed.

During a test an inclined plane bed is tilted at a rate of 1.5°+/- 0.5° per second by and electric motor until the test sled begins to slide. The initial movement of the sled is the slide angle or coefficient of STATIC friction of the material. When the test sled begins to slide a photo-optical sensor automatically stops the inclined plane bed. At that position the angle is measured and recorded, and the tangent of that angle is displayed. This represents the Coefficient of STATIC friction.

A variety of factors can affect the slide angle measurement including abrasion, coatings, varnishes, printing, temperature and humidity.

The CF-200i Inclined Plane Co-efficient of Friction Tester determines the static friction properties of plastic films, foils, laminates, papers and boards

The equipment performs tests to recognised International Test Standards including ASTM D4918, G219, TAPPI T815, T503, T548 and NFQ 03083.

Introduction

Slide angle friction is a measurement of a sheet like substrate such as paper, plastic film, thin board, corrugated board etc. which determines the angle of inclination at which one substrate affixed to a sled will begin to slide/slip against another substrate of a similar material affixed to a bed.

During a test an inclined plane bed is tilted at a rate of 1.5°+/- 0.5° per second by and electric motor until the test sled begins to slide. The initial movement of the sled is the slide angle or coefficient of STATIC friction of the material. When the test sled begins to slide a photo-optical sensor automatically stops the inclined plane bed. At that position the angle is measured and recorded, and the tangent of that angle is displayed. This represents the Coefficient of STATIC friction.

A variety of factors can affect the slide angle measurement including abrasion, coatings, varnishes, printing, temperature and humidity.

Applications

Paper, plastic film, packaging films, paperboard, corrugated board, foils, and other sheet like materials.

Specifications

Digital touch screen panel for setting up test and selecting test speed.

Displays slip angle and tangent of angle.

Automatic sample counter.

USB output of up to 200 results, csv format.

0 to 80° tilt angle of bed.

Variable bed speed 0.5°/sec to 3.0°/sec in 0.5° steps.

Bed dimensions 265mm x 150mm.

Photo-Optical sensor to detect the sled movement and end the test.

Conforms to ASTM D4918, G219, TAPPI T815, T548, T503, NFQ 03083 and ASTM D202 with optional test sled.

Features

Touchscreen colour display showing results and simple set-up of test speed.

Motor-driven tilting of inclined plane bed.

Accurate measurement of slip angle and tangent STATIC coefficient of friction.

Photo-Optical sensor automatically stops the test after initial sled movement.

Measures slide angle and tangent STATIC coefficient of frictio