|

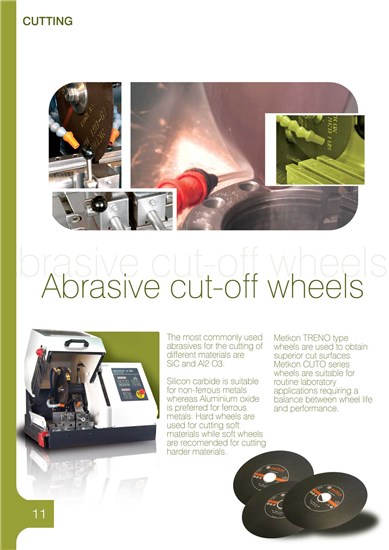

Abrasive Blades:

These high quality Abrasive Cutting Blades are compatible with competitive metallographic cutters. Special order blades can also be obtained for larger diameter cutting blades (16" and 20"). Abrasive blade cutting guidelines

|

|

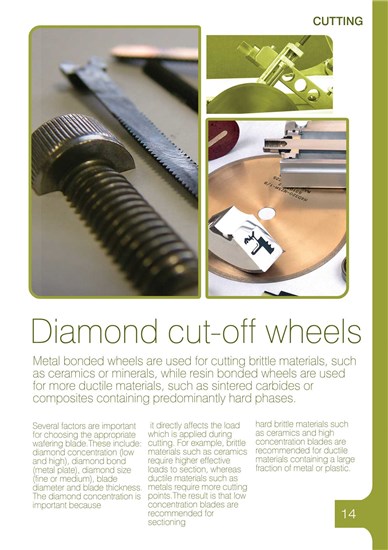

| Wafering Blade : Diamond wafering blades for cutting extremely brittle microelectronics to extremely hard ceramics. The diamond blades vary in diamond grit size, concentration, and blade size. Wafering blade cutting guidelines |

|

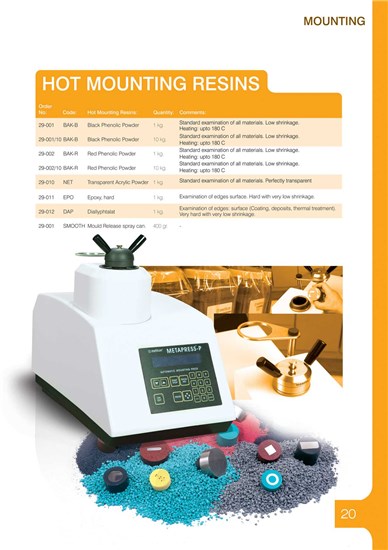

Compression Mounting Resins are specifically designed for mounting at elevated temperatures and pressures in compression mounting presses. Typical compression mounting resins include thermoplastics (clear acrylics) and thermosetting resins (phenolics, epoxies and diallyl phthalates).

|

|

|

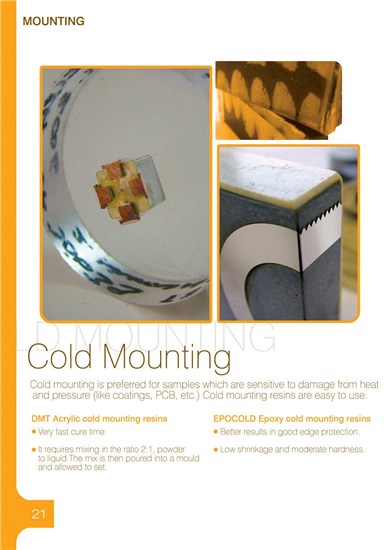

Castable Mounting Resins or cold mounting resins are room temperature mounting resins which typically require at least two parts (resin and hardener). Castable mounting is the preferred mounting technique for brittle materials such as microelectronics. Castable mounting guidelines

|

|

|

Grinding Paper

SiC (PSA) / SiC (Plain-backed)

ALO (PSA) / ALO (Plain-backed)

Zirconia (PSA)

Belt and Rolls

Silicon carbide (SiC) is a very hard and sharp abrasive for cutting metals and polymers. For very coarse removal, zirconia is a tougher abrasive than SiC. Grinding guidelines

|

|

| Composite Disc As an alternative to grinding paers and coarse polishing pads these pre-charged composite disks reduce the need for multiple ginding grinding and coarse polishing papers. Compsite disk guidelines |

|

|

Lapping Film

SiC films

Alumina

Diamond

Lapping films are fixed abrasives on a mylar film. Lapping films are very useful for precision surface finishing and polishing for electronic materials, with applications where flatness is very critical. Guidelines

|

|

|

Polishing Pad

PSA backed

Magnetic Rubber backed

Magnetic Stainless backed

- In order to obtain an accurate representation of the true microstructure, the damage produced during sectioning and mounting must be eliminated. This is accomplished by matching the appropriate abrasive with the correct polishing pad.

|

|

|

Diamond Abrasives:

Polycrytalline suspensions

Monocrystalline suspensions

Paste

-PC diamond is a synthetic diamond which produces enhanced surface finishes and higher removal rates than monocrystalline diamond. The use of lapping lubricants can help remove grinding swarf, reduce corrosion and extend the life of the diamond.

|

|

|

Nanometer Alumina :

is a colliodal alumina produced by a proprietary process which significantly improves the particle size distribution and increases the hardness of the alumina particles. Thus nanometer alumina is the ideal polishing abrasive for a wide range of metals and composites.

|

|

|

Colloidal Silica :

is a relatively soft abrasive with a high chemical activity. It is an ideal chemical mechanical polishing abrasive (CMP). The combination of chemical polishing with mechanical polishing increases polishing rates and improves surface finishes. It is the ideal abrasive for polishing ceramics. Combinations of colloidal silica with the polycrystalline diamond slurries have also been very successful for the intermediate polishing steps for ceramics and ceramic composites.

|

|

|

Cleaning :

Prior to microstructural examination residual abrasives and lubricants must be removed. Proper cleaning and drying techniques improve the final micrographs and thus improve qualitative and quantitative examination of the specimen surface.

|

|

|

Etching :

To aid in the analysis of a materials microsctructure, etching is often used to bring out or highlight specific features.

|

|

| |

|