Deflection Temperature Under Load Tester 303 HDTM

The Model 303 HDTM is the smaller of the two models of DTUL/Vicat test equipment and is capable of testing up to three different specimens simultaneously, using an automated testing sequence that proceeds according to user defined control and configuration parameters.

The machine is supplied as standard with two test stations and, optionally, one more can be added. All stations are pneumatically raised from the oil bath at the touch of a button allowing easy placement of the test specimens. Once loaded, the test stations are lowered into position and the test can be started either from the handheld controller, or from an attached pc running Tinius Olsen’s HDV software.

The machine also features air bearing guided loading rods on each test station to ensure smooth load application and precise measurement of displacement. Additionally the test stations feature a ‘catch basket’ that is designed to catch any test specimens that may become dislodged during the test, so keeping the oil bath as clean as possible. Once the test is complete for all stations, the cooling cycle, using tap water as the coolant, starts automatically to allow more testing.

Deflection Temperature Under Load Tester 603 HDTM

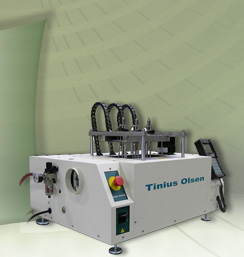

The Model 603 HDTM is the larger of the two models of DTUL/Vicat test equipment and is capable of testing up to six different specimens simultaneously, using an automated testing sequence that proceeds according to user defined control and configuration parameters.

The machine is supplied as standard with two test stations and up to four more can be added. All stations are pneumatically raised from the oil bath at the touch of a button allowing easy placement of the test specimens. Once loaded, the test stations are lowered into position and the test can be started either from the handheld controller, or from an attached pc running Tinius Olsen’s HDV software.

The machine also features air bearing guided loading rods on each test station to ensure smooth load application and precise measurement of displacement. Additionally the test stations feature a ‘catch basket’ that is designed to catch any test specimens that may become dislodged during the test, so keeping the oil bath as clean as possible. Once the test is complete for all stations, the cooling cycle, using tap water as the coolant, starts automatically to allow more testing.